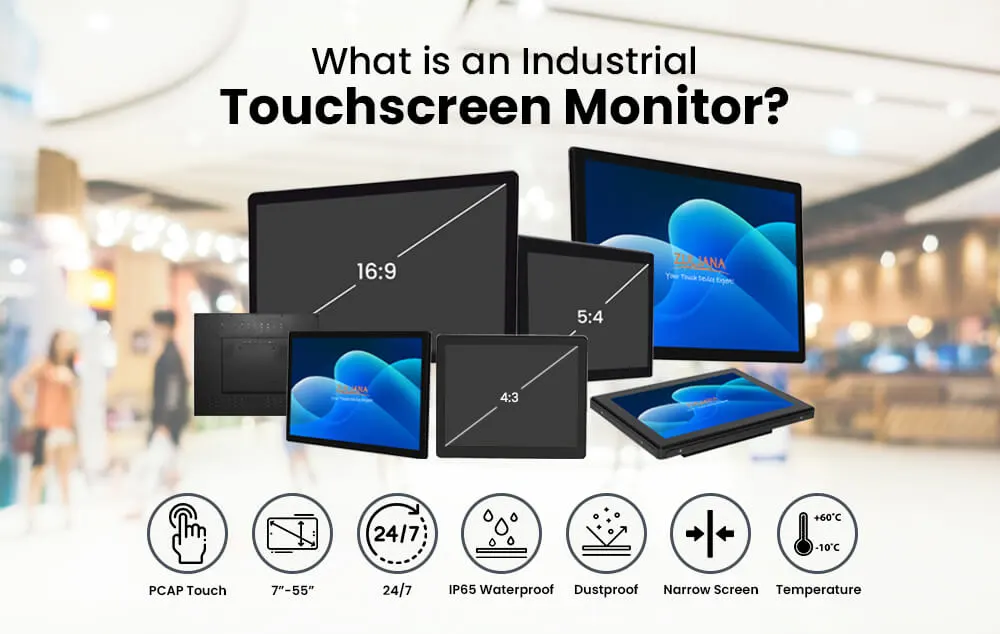

Industrial touchscreen monitors are special screens designed for tough places like factories and warehouses. With these monitors, you have access to control the machines, keep an eye on important features, and run equipment just by touching the screen. Unlike regular monitors, they are super strong. This means they can handle dust, water, and bumps without breaking.

Workers use industrial touchscreen monitors in many jobs, especially in factories, to keep everything running smoothly and improve efficiency. They make it easier for people to use technology.

Industrial touchscreen monitors are used in many jobs, especially in factories, to keep everything running smoothly and improve efficiency. They also make it easier for people to use technology.

We are manufacturing one of the best industrial touch screen monitors.

Type of Industrial Touchscreen Monitors widely used in Europe

Open Frame Monitors

Open-frame monitors are monitors that do not have a full case or enclosure. They have exposed edges, making it easy to install them into a custom frame or kiosk. These monitors are designed to fit into different environments, like self-service machines or digital signage displays. In simple terms, they are flexible monitors that can be built into other equipment or structures.

Panel Mount Monitors

Panel-mount monitors are touchscreen monitors placed directly into machines or control panels. They’re often found in places like factories or control rooms where space is limited. These monitors show important information clearly, helping workers stay on track. Since they fit neatly into the machinery, they keep everything organized and make it easier for everyone to work efficiently.

Waterproof Monitors

Waterproof monitors are made for tough environments, especially where there is water or liquids. They have special ratings, like IP65, which means they can resist water and dust. This makes them perfect for kitchens, factories, or outdoor settings. Workers can use these monitors without worrying about spills or splashes ruining them.

Major Components of Industrial Touchscreen Monitors

- Touchscreen Panel: This is the part you touch to interact with the monitor. It senses your finger and lets you control what you see on the screen.

- Display Screen: The display screen shows all the information, like a TV screen. It uses LCD or LED technology to make pictures and text clear and bright.

- Controller Board: This tiny computer inside the monitor processes touch signals. It helps the monitor understand what you want to do when you touch the screen; therefore, it responds quickly to your actions.

- Enclosure: The enclosure is the sturdy outer shell. It protects all the parts inside and keeps them safe from bumps and dust.

- Power Supply: This component gives power to the monitor. It makes sure everything works properly and can handle different power needs.

Types of Touchscreen Use In Industrial Touchscreen Monitors in Europe

When we talk about the types of screens in industrial touchscreen monitors, we find many options. Furthermore, each type has unique features that make it different from the others. Therefore, let’s discuss some of these types!

Capacitive vs Resistive Touchscreens

First, we have capacitive touchscreens. These screens are very sensitive. They can detect your finger even when you just lightly touch them. This makes industrial touchscreen monitors more responsive for busy places where quick action is needed.

Next, we have resistive touchscreens. These screens work differently. They need a little more pressure to respond. You can use your finger, a stylus, or even a gloved hand. They are often used in places where dirt or water might be a problem. We have listed a detailed post about the difference between resistive and capacitive touchscreens.

Projected Capacitive Touchscreens

Projected Capacitive Touchscreens are a type of touchscreen that offers better sensitivity and allows for multi-touch. This means you can use more than one finger at a time, like pinching to zoom or swiping. These touchscreens are very useful in factories, where workers need to quickly control multiple tasks at once.

Infrared Touchscreens

Finally, we have infrared touchscreens. These screens use light to sense where you touch. They are great because they can work with any object, not just fingers. This means you can use a tool or even your elbow! They are tough and can handle a lot of different environments.

Key Features of Our Industrial Touchscreen Monitors

Our Industrial touchscreen monitors have special features that make them perfect for tough jobs. Let’s explore some of these important features!

- Durability: These monitors are built strong to survive tough conditions like heat, cold, dust, and moisture. They can handle the roughness of factories or outdoor environments.

- Waterproof and Dustproof: Industrial touchscreen monitors are sealed to keep out water and dust, perfect for places like factories, kitchens, or outdoor sites.

- Multi-Touch Support: They can detect multiple touch points at once, letting you use gestures like pinch-to-zoom or swipe, just like on a smartphone.

- Wide Temperature Range: Industrial monitors keep working in extreme temperatures, from freezing cold to blazing heat, making them suitable for almost any environment.

- High Brightness: With extra-bright screens, these monitors stay clear and readable, even in direct sunlight or brightly lit areas. You can read our guide on what a sunlight readable monitor is.

- Vibration and Shock Resistance: They are designed to function smoothly even when exposed to constant vibration or shocks from nearby machinery.

- Long Lifespan: Designed for continuous use, they can run 24/7 without breaking down quickly, which is important in industries that never stop.

- Anti-Glare and Anti-Reflective Coating: Industrial touchscreen monitors have special coatings that reduce reflections and glare, making the screen easier to read, even under bright lights.

Applications of Industrial Touchscreen Monitors

Industrial touchscreen monitors are used in many different industrial appliances like Kitchen Display System, Que Management Kiosk, Drive Though Menu Board, and many more. Let’s look at some of the important ways they help people in their jobs!

- Manufacturing Facilities: These industrial monitors help workers watch machines and control production lines. They make it easy to keep everything running smoothly.

- Warehouses: In warehouses, industrial touchscreen monitors track items and help workers know where to find things. This keeps shipments organized and on time.

- Energy Sector: Industrial touchscreen monitors are also used in the energy sector where they help to check equipment and manage energy flow. They keep our lights on and our devices working.

- Oil and Gas Industries: In drilling sites, these monitors show real-time data about the equipment. Workers can quickly respond to any issues that come up.

- Healthcare Settings: In hospitals, industrial monitors are also available to track patient health and provide important information to the doctor. They are very helpful to handle things easily.

- Automotive Industry: Factories use touchscreen monitors to manage assembly lines. They help workers build cars efficiently and fix any problems.

Benefits of Using Industrial Touchscreen Monitors

Enhanced User Interaction

Industrial touchscreen monitors are easy to use. Instead of using a mouse or keyboard, you can simply touch the screen, which makes it faster to find what you need. For example, imagine playing a game where you just tap on the screen instead of using buttons; it’s both fun and simple. Additionally, these screens are very clear, so you can see everything easily. As a result, this clarity helps workers understand what to do without confusion.

Improved Efficiency and Productivity

When workers use touchscreen monitors, they can work faster. Touching the screen is quicker than typing on a keyboard, so tasks get done more quickly. Furthermore, if someone needs to check information, they can simply tap a button instead of searching through files. This speed helps companies finish projects on time and boosts overall productivity. Ultimately, when everyone works efficiently, the team can feel proud of their accomplishments.

Space-Saving Designs

Industrial touchscreen monitors come in different sizes, and many are slim and sleek, which means they don’t take up much room. Space is important in a busy factory or workshop. With these monitors, there’s more room for other tools and equipment. Workers can move around easily without bumping into big machines. A tidy workspace helps everyone stay organized and focused on their tasks.

Conclusion

What is an industrial touchscreen monitor? It’s a powerful tool that helps people work in tough environments. These monitors come in types like open frame, panel mount, and waterproof, making them versatile for different uses. ZULJANA also manufactures the best industrial touchscreen monitors.

Durable components and features like multi-touch support allow workers to interact easily with machines. Overall, industrial touchscreen monitors are essential in modern industry, helping everything run smoothly and efficiently.