BAOBAO Technology NEWS

BAOBAO INDUSTRIAL LATEST NEWS

Recent Posts

How We Solved a Problem for Our Customer in Italy

April 25, 2025

Benefits of Using a Self Service Kiosk in Restaurants

April 22, 2025

How to Maintain Your Industrial Touchscreen for Longevity

April 22, 2025

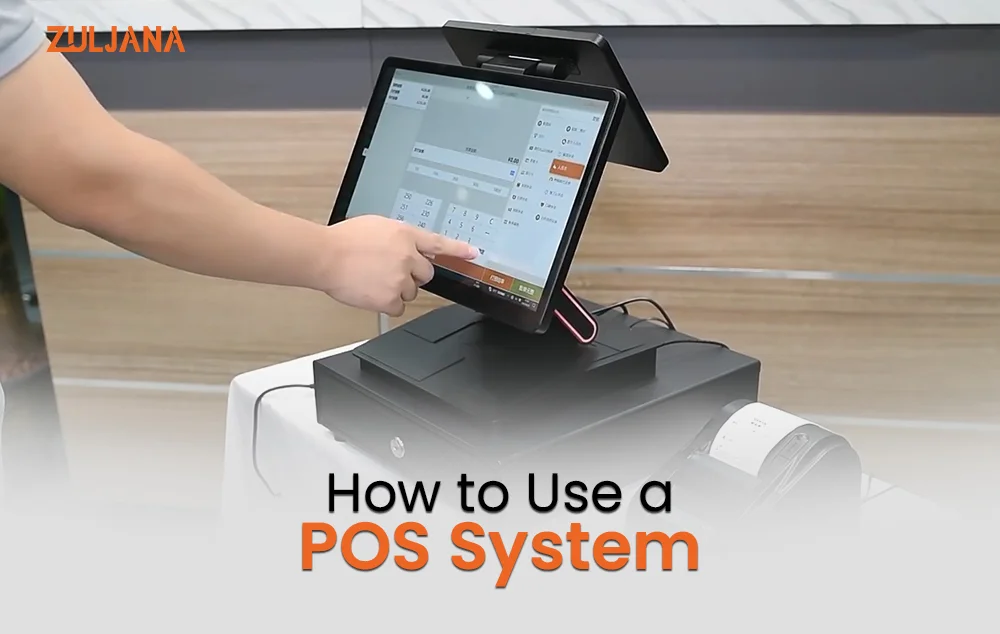

How to Use POS System | Complete User Guide

April 22, 2025

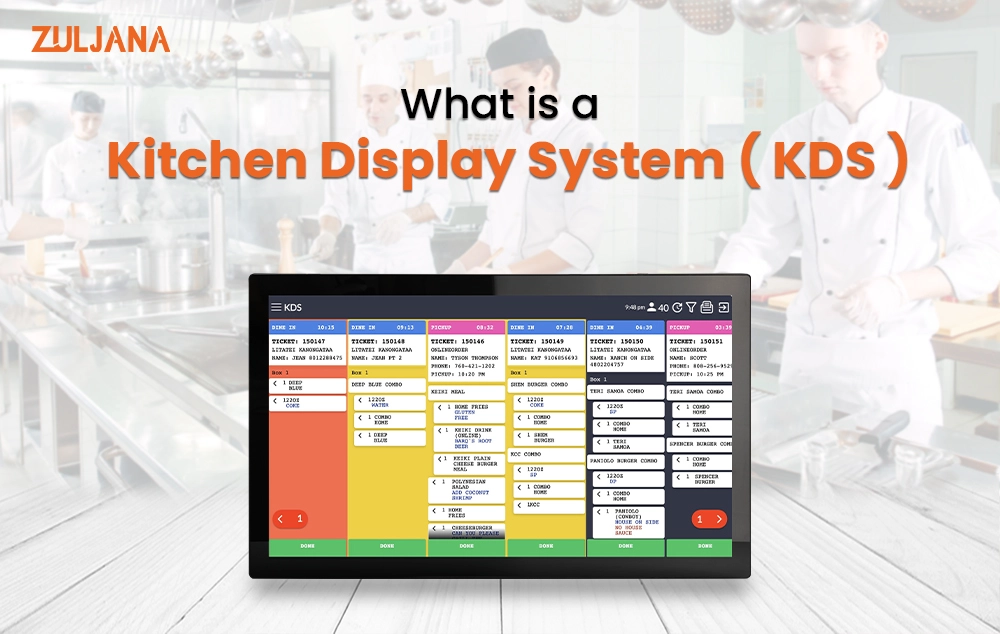

What is a Kitchen Display System ( KDS )

January 20, 2025

Want to Know More About Us

Check out our awesome touch screens.

Discover what makes our touch screens more demanding.

See how BaoBao Technology started small and now helps businesses around the world with our smart and reliable products!